Whisky Scotland’s national drink, has been lovingly crafted throughout the country for ever. THERE ARE over 100 working distilleries operating today, each making whisky in their own unique way.

STEP 1: MALTING THE BARLEY

Barley contains starch and this needs to be converted into soluble sugars to make alcohol. The barley must germinate and this is called Malting. Each distiller has their own preference about the type of barley, but it has to be the type giving high yields for fermentation. The barley is steeped, drained and steeped again several times over about a 48 hour time period before going to malting and is spread on a stone floor called a malting floor for 5 to 7 days.

The barley is turned regularly to maintain a constant temperature and to stop the grains sticking together. When the barley has started to shoot, the germination is stopped by drying it in a kiln which is similar to a giant tumble dryer. In a distillery, the barley in the kiln above a fire which is coal or a mixture of coal and peat. If peat is used for drying the peat smoke can influence the flavor of the final spirit. The dried barley is now ground down in a mill, after debris such as mall stones etc. have been removed. You then have grist.

STEP 2: MASHING THE BARLEY

The ground barley, or ‘grist’, is mixed with hot water, the water will come from a pure, reliable local source. It can contain minerals or peat flavors from the terrain it passes through in a mash tun and heated and cooked for several hours producing a sugary liquid called ‘wort’. This is the basis for the alcohol. The remaining solids are used as a nutritious cattle feed.

During this process, the sugars in the malt dissolve and theses are drawn off through the bottom of the mash tun This liquid is now called ‘wort’ The process is completed three times with the water temperature getting hotter each time. Only wort from the two mashing’s are used. The third is put back in with the next batch of grist.

Primary conversion occurs in the mash tun and accounts for 75-80 per cent of the total process. While secondary conversion while 20 to 25% successful conversion takes place in the wash back and refers to the remaining 20-25%. Successful conversion is critical to maximize the yield of alcohol and depends on the actions of three key enzymes in the barley. When the mashing begins with the grist being combined with hot water at 63.5 degree centigrade. Enzymesare heat sensitive and active/inactive within different temperature ranges, with the 63.5 degrees centigrade a compromise temperature that enables the alpha amylase and beta amylase performs better at a higher temperature while beta amylase prefers is cooler.

The heat of the water also solubilizes/dissolves the starch within the grist and when this happens both enzymes can begin to get to work. By the end of the fermentation process around 85 to 87% of the original starch level is converted and turned into alcohol; this is about the maximum we can achieve. If the temperature of the mash is hotter or cooler than the optimum temperature of 63.5 to 64 degrees centigrade it can compromise the process efficiency and yield. They take of the wort on a regular basis to check but most of the time it goes very smoothly.

The consequences of the process not going to plan are. If the water temperature was slightly off you could lose about 15 to 20 liters of alcohol per ton of barley compared to the typical 41- to 420liters. This can also result in a wash with a slightly lower alcoholic strength than usual. But this would not require and adjustments to the distillation process in order to maintain the usual spirit character.

STEP 3: FERMENTING THE WORT

The liquid wort is cooled and passed into large vats called ‘washbacks’. These are traditionally made of Oregon Pine, but now a number of distilleries use stainless steel. Yeast is then added and allowed to ferment which converts the sugars in the wort into an alcohol at around 8% ABV. This liquid, similar to a strong beer, is now known as the ‘wash’. The Fermentation is usually complete within two days. From now on though this Whisky journey, the liquid is distilled rather than brewed.

STEP 4: DISTILLING THE SPIRIT

In Scotland the wash is traditionally distilled twice although there are exceptions. The liquid wash is heated in two copper pot stills, the wash still and the spirit still. Only the highest quality part of the spirit, the heart of the run, is collected and poured into oak casks to age. The rest is siphoned and re-distilled.

Here is how double distillation works The copper still consist of a bowl shape at the bottom that rises up to the swan neck at the top. Different shapes gives different characteristics to the final spirit Tall still with longer necks give finer, lighter spirits where short fat stills will produce a fuller, richer spirit although there are exceptions. The angle of the lyne arm at the top of the still also has an effect.

Firstly the wash enters the still and is heated usually by gas or steam. The liquid rises up the still until it reaches the neck, where it passes along the lyne arm and then condenses in a worm, basically a coiled metal cooling tank. This liquid is now blow wines 20% ABV. Any residue from the wash still known as pot ale is collected and used to manufacture farm feed or fertilizer. The low wines are passed to the second still, called the spirit still for the second distillation approx. 68-74% ABV.

The liquid then passes into the spirit safe. In the spirit safe, the alcohol runs through three stages. Alcohols from the beginning called foreshots are very high I alcohol level and pungent. Alcohols from the end called feints are weaker but also pungent and more viscous. The alcohol in the middle or heart of the distillation is just right and this is diverted to the receiving tank to go on for maturation. The foreshots and feints are mixed with the next batch of low wines and redistilled. The residue left in the still is called spent lees and will be discharged as waste. The heart of the spirit is then taken to be matured and that will become whisky. The whole process is still very much a craft, and the eye and hand are preferred over a computer.

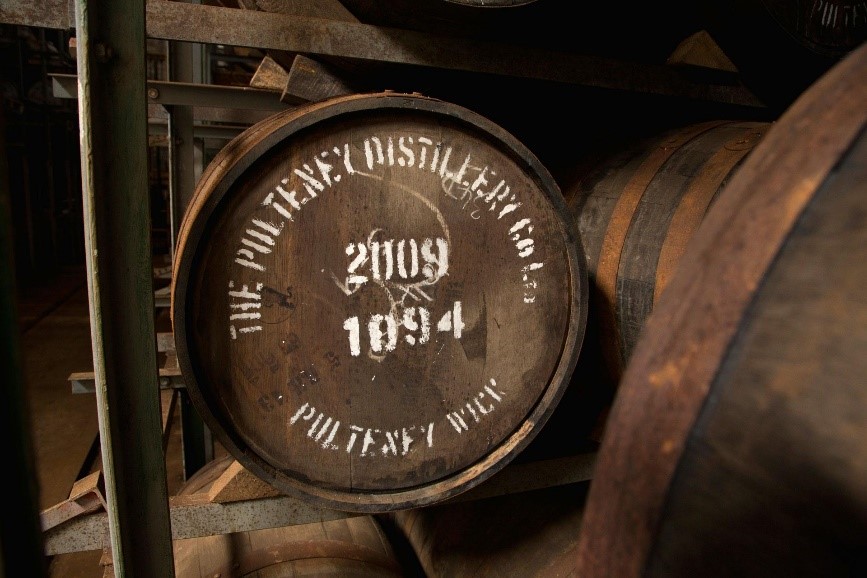

STEP 5: MATURING THE SPIRIT

The last part, to become Whisky, the clear spirit has to be put in oak casks and stored. By law, whisky cannot be called Scotch unless it has been matured for a minimum of three years in oak barrels. The most common types of oak casks are those that have previously been used in the American Bourbon and Spanish sherry industries or have been used to mature Whisky before. Barrels may have contained sherry, port, whiskey or beer, which along with the oak influences the flavor. If an age is shown on a label of blended whisky, it indicates the age of the youngest whisky in the blend.

This is changing and lots of other wine and spirit casks are now used to create what they call finishes. Rum, wine, port even Calvados casks are used to impart unique and exciting flavor nuances. Some distilleries also use virgin oak which has just been charred.

During maturation, the flavors of the spirit combine with compounds in the wood cask and this gives the Whisky its own characteristic flavor and aroma. Wood is porous, so over time it will breathe in air from the surrounding environment in which it is stored. This will also give the Whisky some unique characteristics.

If the distillery storage facilities are next to the sea, or on an island or in the middle of the highlands then the air quality, temperature and humidity will be different and influence the end product.

During each year of maturation about 1-2% of the spirit is lost through natural evaporation and also loses a little in strength each year, called the “The Angels Share” this explains some why older Whisky’s are less readily available and tend to cost more to buy.